Die Design Tool Room

The die design and manufacturing is a state of the art facility

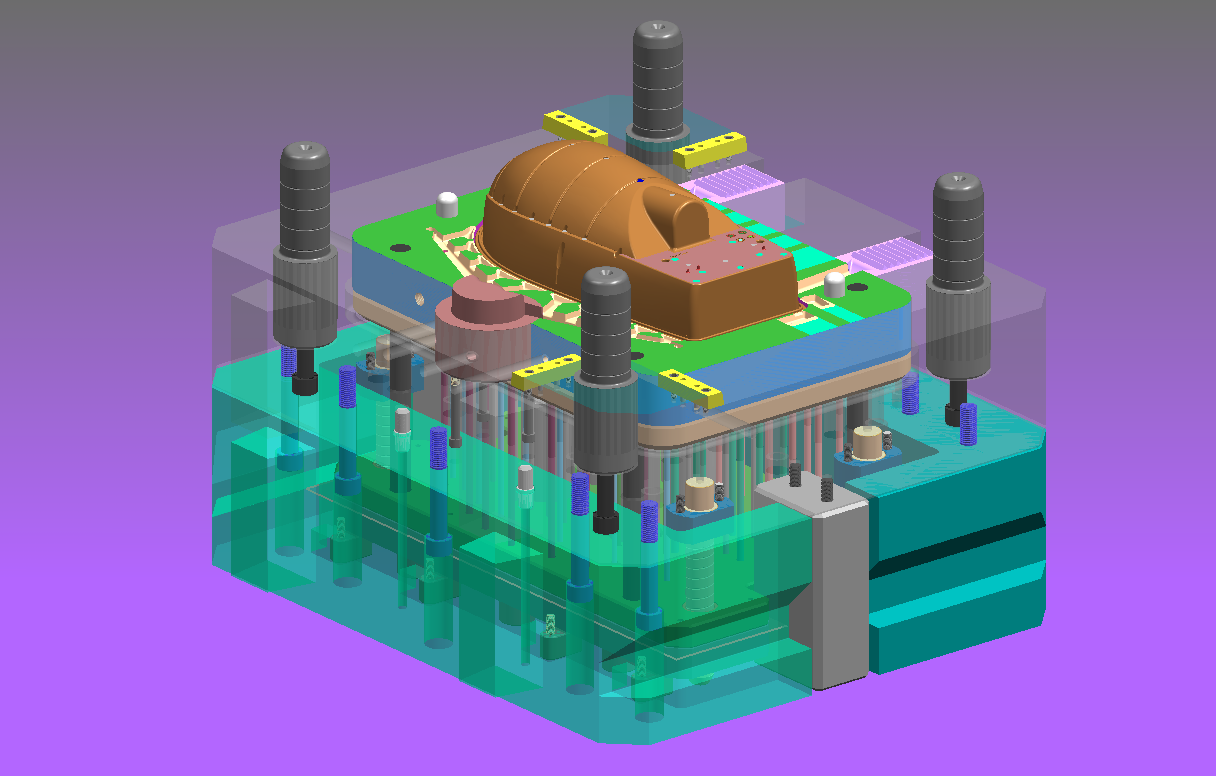

Die design capability

The design stations are manned by die design experts who continuously hone their skills through new developments and customer interactions.

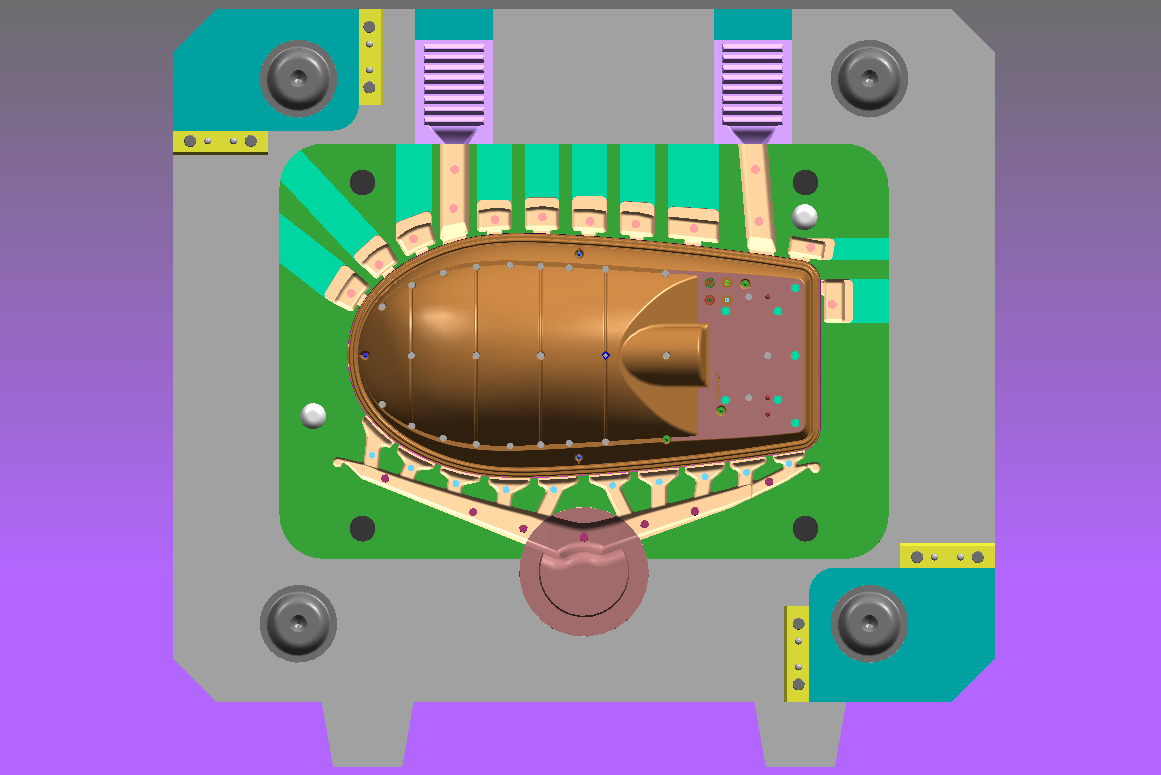

3D Modelling

The die design facility at Palwal is capable of 3D modelling and simulation and manufacturing of the dies using the CAD files.

Prototyping

Rapid prototyping and established manufacturing allows the plant to convert the concept to a manufactured part in a short period of time.

Large database

The experience in die manufacturing is stored in the form of a large database on the server and is referred to by the design experts .

HDPC dies

The Tool room facility churns out the most complex dies with relative ease

LED Street Light

3D Design

Ready for manufacturing

LED Street Light

HPDC Die for production

Die manufactured in TR

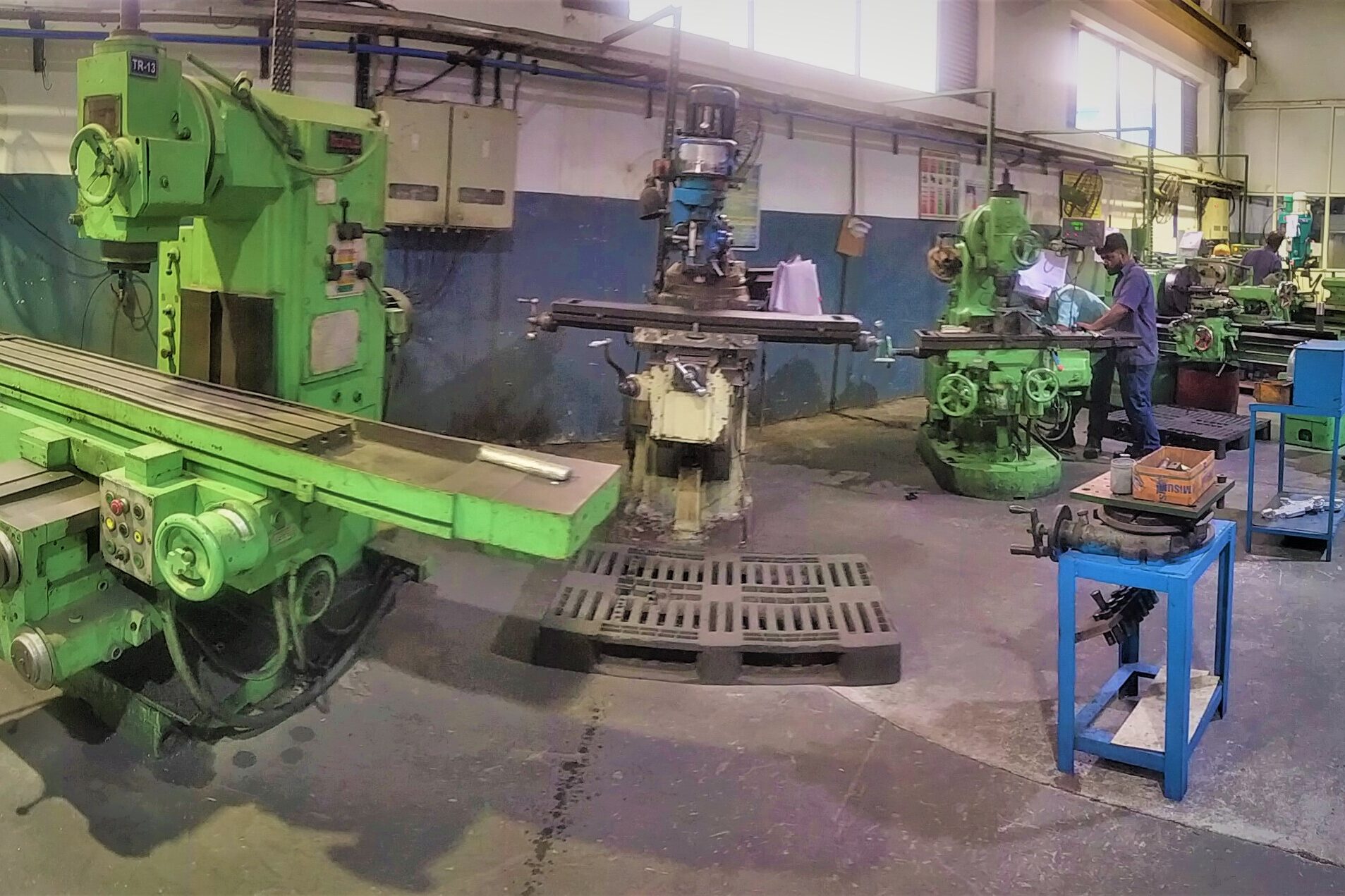

Conventional machining

Tool Room machines

Milling, grinding, drilling etc.

Dies in production

Tool Room manufacturing

State of the art facility

Tool Room

The capability of the tool room is greatly enhanced with the following two machines:

1) Deckel Maho Germany VMC

2) Mazak Japan VMC

which are currently located at the Esko Kolkata facility.

Tool Room

The tool room at Palwal is equipped with the following machines:

1) Wire Cut

2) EDM Die Sinkers-2

3) VMC -2

4) CNC Lathe 2M

5) Conventional machines-16

The machines are of reputed make like HAAS and Accutex and cater well to the manufacturing requirements of the dies.