Quality Systems

Quality Management System (QMS) is part of the culture at Esko.

3D CMM

The Spectra 3D CMM machine forms the backbone of the Quality Management System at the Esko Casting and Electronics Pvt Ltd. The highly accurate measurements are used to establish new products dimensions and carry out the audit checks of existing products. The machine is utilized extensively in the new product development exercise. The parts measured on the 3D CMM form an important inclusion of the APQP and PPAP processes.

Spectrometer

The aluminium alloy composition is certified using the Spectrometer. The alloys are checked right at the input stage on receipt at the input store. The alloy suppliers are kept under check through the spectrometer reports as the failure results in lot rejection. The Quality Management System is utilised right from the input stage to ensure that the right product is delivered to the customer.

Contour tracer

The Contour tracer from Mitutoyo is utilized for measurement of typical contours that are so very critical for customer specific products. The accurate part profiles and their measurement gives confidence to the customer about the Quality Management Systems at Esko Casting and Electronics Pvt Ltd.

Profile projector

A number of profiles are checked on the profile projector to ensure the quality of the products being shipped to the customer. It is not necessary to check all the profiles on the contour tracer as the profile projector gives a fairly accurate measurement. The reports which form a part of the Quality Management system are well suited for meeting the desired customer specifications.

Quality Equipment

Spectro

HPDC

Incoming material inspection

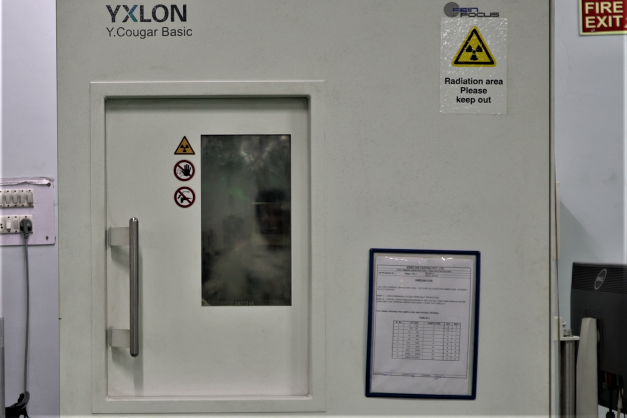

X Ray

EMS

Production part inspection

Density Index

HPDC

Molten metal inspection

Contour Tracer

HPDC

Quality Assurance

QMS – Certifications

Quality Management System

The quality levels are both measured inside the plant as well as at the customer end and reported on a monthly basis with countermeasures for improvement.

Certifications: The plant is certified for TS-16949-IATF quality system. Certification and surveillance audits are held at regular intervals.